I ask those last two questions because nobody sells 10 or 20 weight non detergent in my area n I'm not sure the modern recommended equivalent for my lathe. Would air tool oil work? (Seems around a ten weight, but does it have any detergent, don't think so but just making sure)Ĭompressor oil? (Seems like that maybe a bit thick, like around a 30w) Replacement babbitt bearings BACK GEAR WITH. What type of oil should I be using 10w or 20w non detergent? FOR ATLAS BABBITT BEARING LATHES: WITH HORIZONTAL COUNTERSHAFT-Cat. If so, should I install some felt into the cup so it gravity drips? In the 45 seconds or so, the bearing with the ball bearing on one side n the retainer rings on the other got a bit warm due to trapped heat, but nothing I'd consider hot.

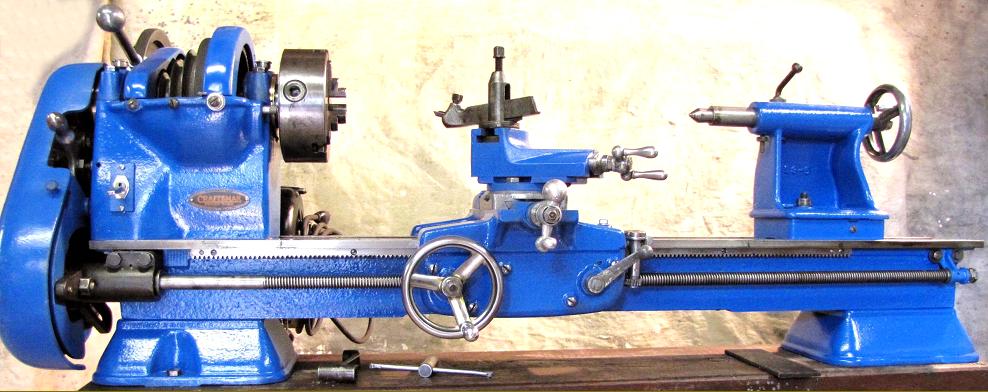

Now there's still oil in the bearing sleeve itself, but the cups are empty. Problem is the oil cups for the spindle do not have any felt pads, and the bearings just have what looks to be holes drilled into them so the pool can pass through, and when I run the lathe, the oil just drips right through the cups into the bearings and out onto the table. Atlas / Craftsman 9, 10 & 12 Lathe Steady Rest Jaws / Fingers with Bearings. From around 1935 until about 1952, someone but probably Timken did 100 inspection of the bearings that Atlas was buying and engraved a date on both the cup and the cone. Last edited by David Utidjian 06-01-2009 at 02:47 AM.So I got it running n for the spindle oil I used automatic transmission dextron (not type f), because it's all I had right now n I heard it wouldn't hurt anything. The manual calls that bearing a "safety valve" (sheesh.) the damn thing is designed to break that part. The new bearings are oil-impregnated bronze bushings.Atlas 618 Craftsman 101.

My Rockwell 10" has instructions for making the shear pins in the manual.*/ĮTA: Ignore everything between the /* */ above I just looked it up in an Atlas manual I have. Here I replace heavily worn countershaft bearings on my 12 Craftsman lathe. has anybody ever done replaced or repoured the babbit bearings in one of these machines and how is it.

I dont know much about Atlas lathes and would not have the slightest idea how to replace or refurb those babbit bearings so that it all ran true to the bed and tailstock. The shear pin would be at the other end of the leadscrew and is usually even easier to replace. A friend has an Atlas lathe, I believe something like a 9' and has told me the babbit bearings in the headstock are bad.

Most lathes in that class have shear pin. I am not familiar with the Atlas/Craftsman lathes but I would hope that it has a better method as a "fuse" for the leadscrew than breaking the bearing bracket. If you have a 4-jaw chuck you could even make it on your lathe. I would fuss and make it from cast iron with bronze bushings. *It looks like it would be pretty easy to make one from a solid block of cast iron or bearing bronze.

0 kommentar(er)

0 kommentar(er)